Rotationswärmetauscher

Die Gas-Gas-Wärmetauscher und Luftvorwärmer von Howden gewinnen Wärme zurück, die andernfalls verschwendet würde, und spielen eine wichtige Rolle bei der Steigerung der Energieeffizienz in einer Reihe von Industrieprozessen.

Howden ist seit dem Aufkommen dieser Technologie vor mehr als hundert Jahren führend bei der Verbesserung des Wirkungsgrads in kesselbasierten Kraftwerken und in der Industrie mit befeuerten Heizgeräten. Bereits in den 1930er Jahren wurde der Erhitzer in REA-Systemen und seither in SCR-Systemen zur Optimierung der Emissionskontrolle eingesetzt.

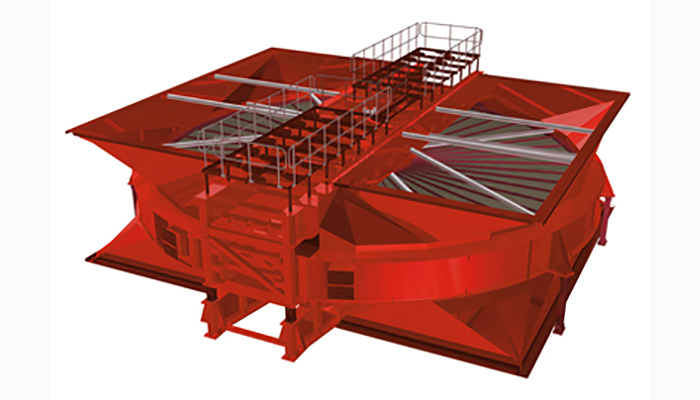

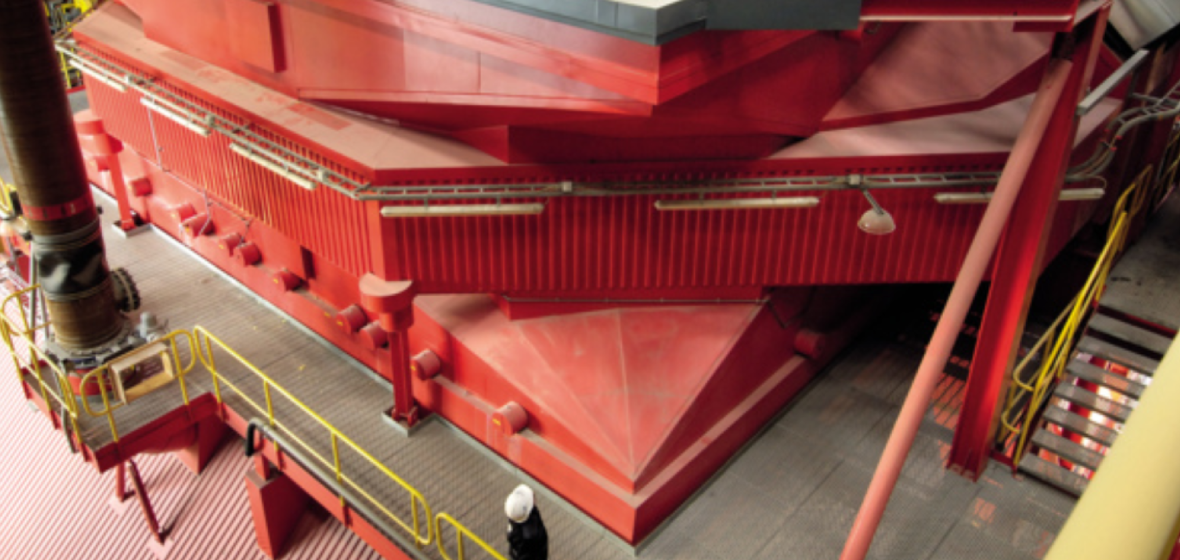

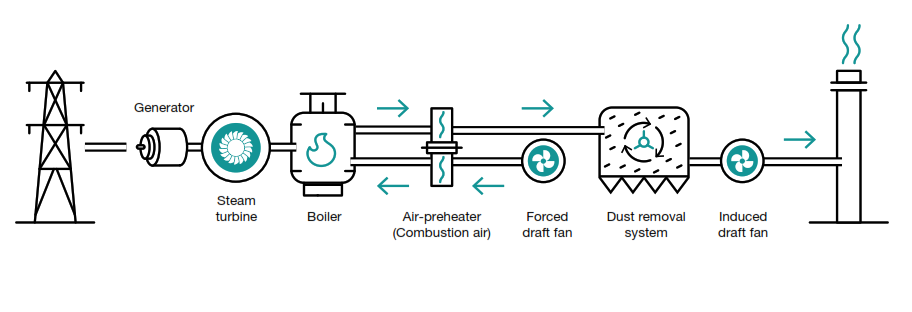

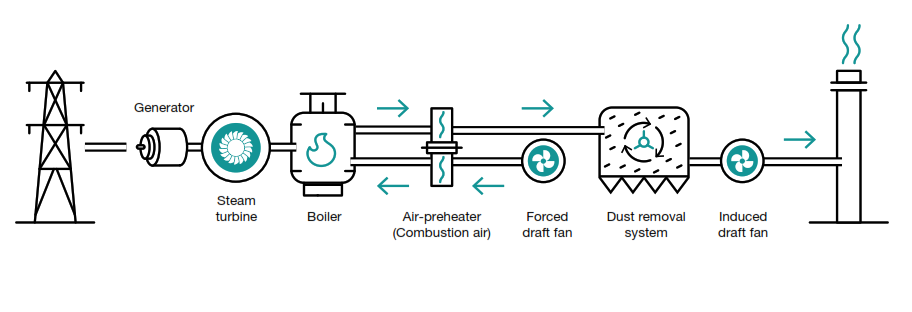

Regenerative Luftvorwärmer entziehen dem Abgas beim Verlassen des Ofens die Abwärme und übertragen diese Energie auf die Zuluft, die im Ofen verwendet wird, um den Sauerstoff für die Verbrennung des Brennstoffs bereitzustellen.

Während sich der Vorwärmer langsam mit etwa 1–2 U/min dreht, nehmen dünne metallische Wärmeübertragungselemente die Wärme aus dem heißen Gasstrom auf und geben sie an den einströmenden Kaltluftstrom ab.

Ziel: die Effizienz von Kessel, Ofen oder befeuertem Heizgerät um 10–15 % zu erhöhen.

Typische Prozesse, die bedient werden

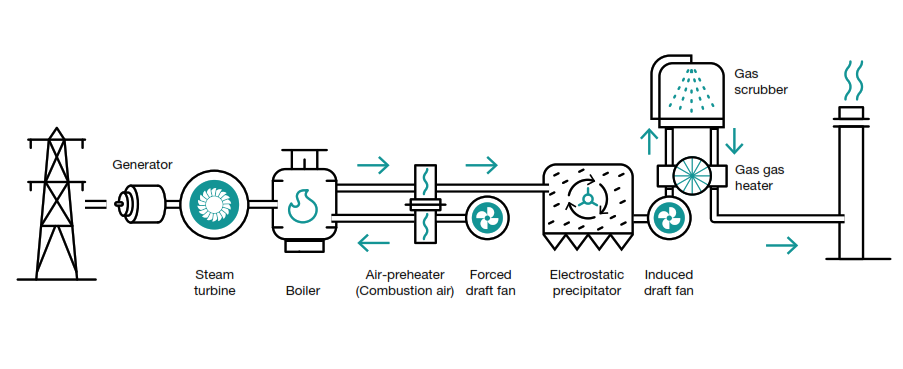

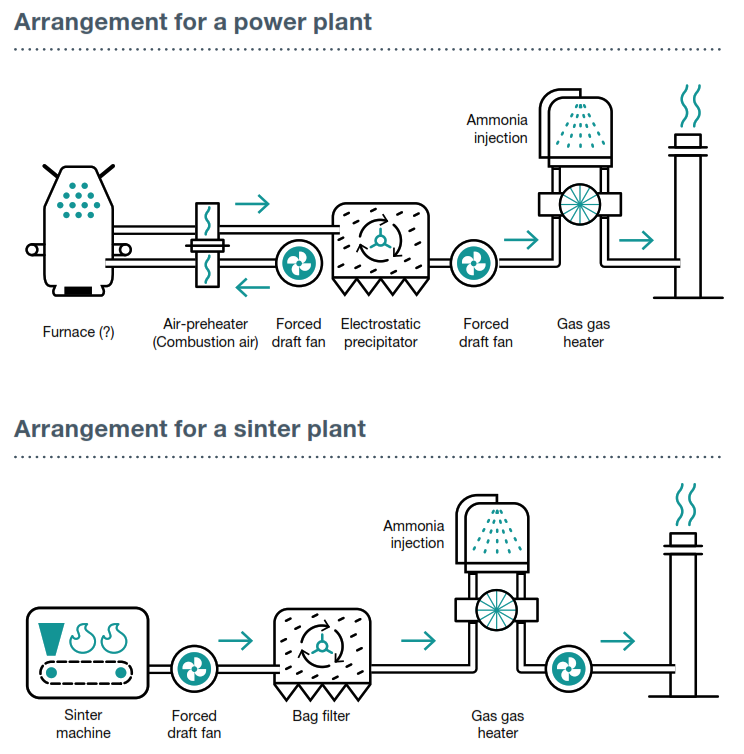

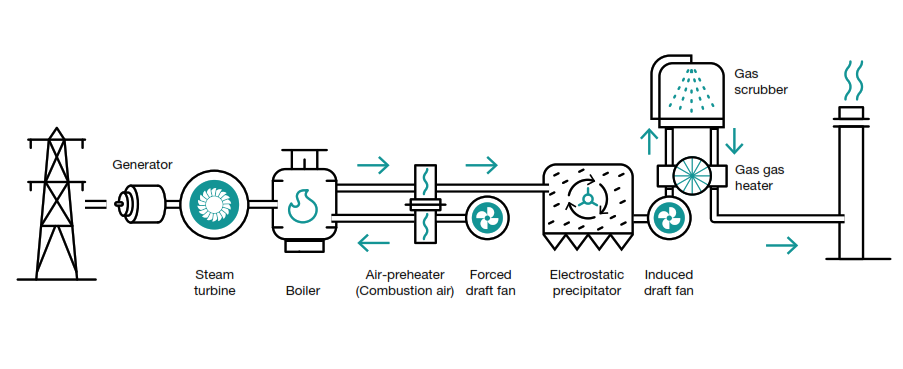

Schwefeldioxid ist ein schädliches, säurehaltiges Gas, das bei der Verbrennung fossiler Brennstoffe entsteht. Mit der Einführung der Rauchgasentschwefelung (REA) zur Emissionskontrolle durch Reinigung des Gases, fand die Rotationsheizung eine weitere wertvolle Anwendung.

Viele Rauchgasentschwefelungsanlagen sind mit Gasüberhitzern (GGH) ausgestattet, um die Rauchgastemperatur vor dem Adsorber zu senken und das behandelte Gas wieder zu erwärmen, so dass ein „trockener“ Kamin entsteht. Dies gewährleistet einen ausreichenden Auftrieb der Abgasfahne und verhindert, dass die SO2-Konzentration am Boden über die festgelegten Grenzwerte hinaus ansteigt.

Der GGH reduziert den Wasserverbrauch im Adsorber und eliminiert die Ableitung von Flüssigkeit aus dem Kamin. Außerdem werden hohe Kosten für die Schornsteinsanierung und Wartungsprobleme aufgrund von Säurekorrosion und Abflussverstopfung vermieden.

Regenerative Gas-Gas-Wärmetauscher gewinnen Energie aus dem Rohgas zurück, wenn es in den REA-Wäscher eintritt, indem sie die Abwärme in dünnen metallischen Wärmeübertragungselementen absorbieren. Die Elemente drehen sich in der Regel mit etwa 0,5–1 U/min, um die Wärme an das behandelte Gas zu übertragen, das in den Schornstein geleitet wird.

Ziel: zur Unterstützung des SOX-Behandlungsprozesses und zur Kostensenkung durch Wiedererwärmung des behandelten Gases auf das erforderliche Auftriebsniveau.

Typische Prozesse, die bedient werden

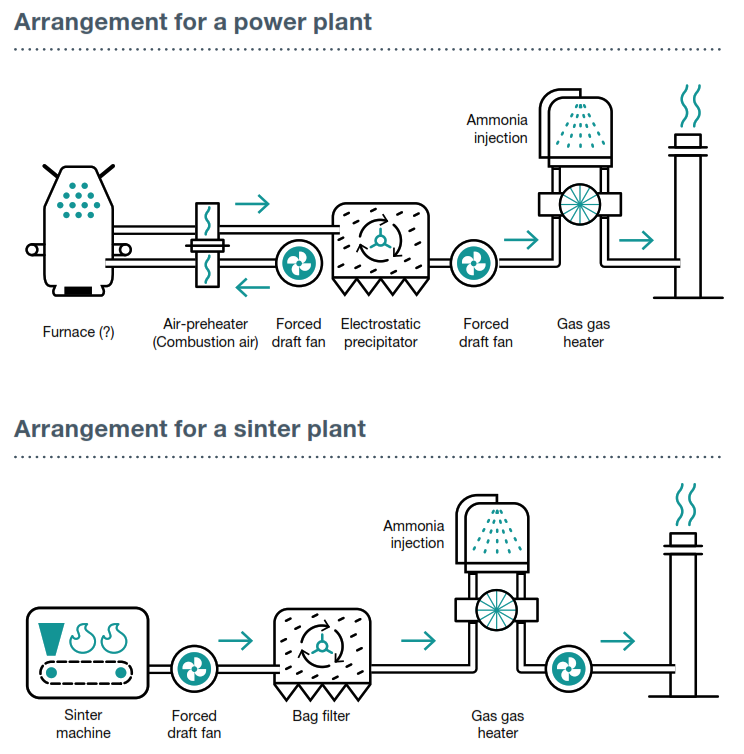

Stickstoffoxid ist ein schädliches Gas, das bei der Verbrennung fossiler Brennstoffe entsteht. Als die selektive katalytische Reduktion (SCR) zur Emissionskontrolle eingeführt wurde, fand die Rotationsheizung eine weitere wertvolle Anwendung.

In einigen Werken, in denen die SCR-Anlage nicht am Economiser angebracht werden kann, wird die staubarme (oder hintere) SCR-Anlage zur Reduzierung der NOx-Emissionen eingesetzt.

Regenerative Gas-Gas-Wärmetauscher (GGH) gewinnen Energie aus dem behandelten Gas zurück, wenn es die SCR verlässt, indem sie die Abwärme in dünnen metallischen Wärmeübertragungselementen absorbieren. Bei dieser Anwendung rotieren die beheizten Elemente mit einer Drehzahl von 0,6–1 U/min, um die Wärme auf das Rohgas zu übertragen und so die zum Erreichen der Reaktionstemperatur erforderliche zusätzliche Erwärmung zu verringern.

Ziel: Zur Erhöhung der Effizienz des NOX-Emissionssystems durch Verringerung der zusätzlichen Heizung, die erforderlich ist, um die Reaktionstemperatur für die Zerstörung von NOX (≈ 250–330 oC) zu erreichen.

Typische Prozesse, die bedient werden

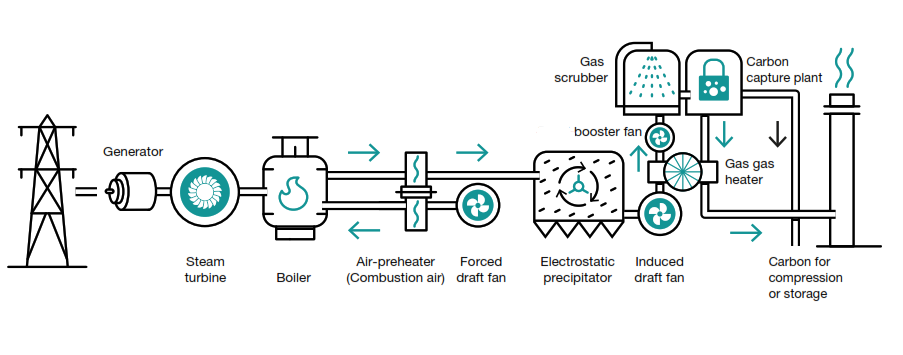

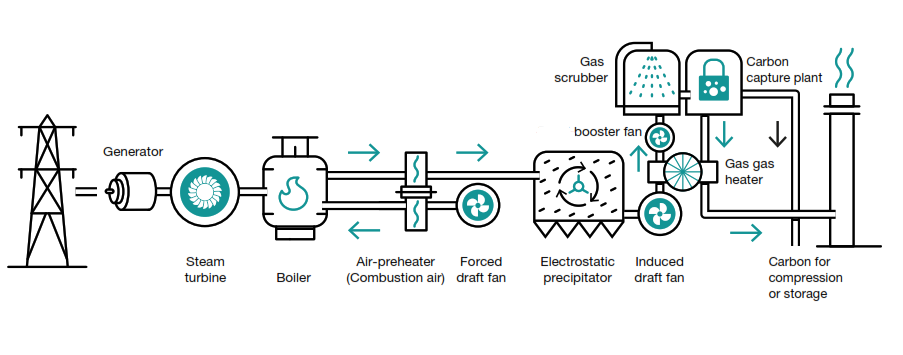

Da die Industrie auf Kohlenstoffabscheidung und -speicherung setzt, wird die Rotationsheiztechnologie in die Entwicklung von Lösungen integriert.

Für neue Kraftwerke werden Post Combustion Capture (PCC)-Lösungen für die Kohlenstoffabscheidung entwickelt. Für bestehende Kraftwerke lassen sich diese nachrüsten. Sie fangen Kohlendioxid (CO2) im Rauchgas ab, um es als Produkt zu nutzen oder dauerhaft unterirdisch einzulagern.

Das Heizgerät für dieses Verfahren ähnelt dem Gas-Gas-Wärmetauscher (GGH) mit ähnlichen Temperaturen wie beim REA-Verfahren. Das Heizgerät kombiniert die Kühlung des Rauchgases vor der FGD-Werk und die Wiedererwärmung des behandelten Gases nach der Kohlenstoffabscheidungsanlage für die Ableitung in den Schornstein.

Ziel: um die Temperatur des Rohgases vor der Abscheideanlage zu senken und das behandelte Gas damit wieder zu erwärmen, um die Sichtbarkeit der Abgasfahne zu verringern und genügend Auftrieb für den Austritt aus dem Schornstein zu haben.

Anwendbare Produkte

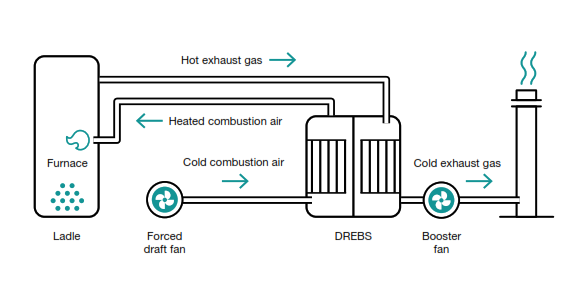

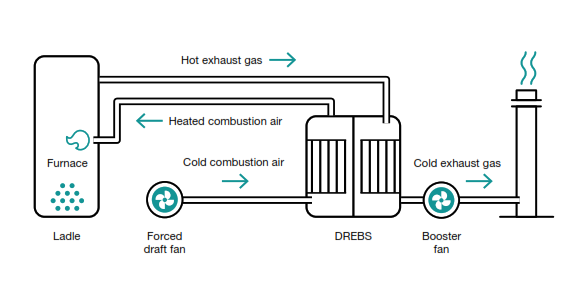

In vielen industriellen Prozessen wird bei hohen Temperaturen gebrannt. Diese Prozesse verbrauchen viel Energie, sodass jede Möglichkeit, den Bedarf zu senken, zu erheblichen Betriebseinsparungen führen kann.

Die Lösung von Howden stammt von unserer Marke Rothemühle und ihrem DREBS-Heizgerät. Hierbei handelt es sich um ein rotierendes Regenerator-Brennersystem, bei dem das Heizgerät die Energie der Hochtemperaturabgase auf keramische Heizflächen überträgt, die dann rotieren und die Wärme an den Luftstrom abgeben.

Im Vergleich zu herkömmlichen Rekuperatoren kann der DREBS für deutlich höhere Temperaturen von bis zu 1200 oC eingesetzt werden. Durch den hohen thermischen Wirkungsgrad von über 85 % kann die Energieeinsparung im Vergleich zu herkömmlichen Rekuperatoren verdoppelt werden.

Ziel: um den Wirkungsgrad von Brennern und Trocknern um bis zu 100 % gegenüber herkömmlichen Wärmetauschern zu erhöhen.

Typische Anwendungen

Regenerative Luftvorwärmer entziehen dem Abgas beim Verlassen des Ofens die Abwärme und übertragen diese Energie auf die Zuluft, die im Ofen verwendet wird, um den Sauerstoff für die Verbrennung des Brennstoffs bereitzustellen.

Während sich der Vorwärmer langsam mit etwa 1–2 U/min dreht, nehmen dünne metallische Wärmeübertragungselemente die Wärme aus dem heißen Gasstrom auf und geben sie an den einströmenden Kaltluftstrom ab.

Ziel: die Effizienz von Kessel, Ofen oder befeuertem Heizgerät um 10–15 % zu erhöhen.

Typische Prozesse, die bedient werden

Schwefeldioxid ist ein schädliches, säurehaltiges Gas, das bei der Verbrennung fossiler Brennstoffe entsteht. Mit der Einführung der Rauchgasentschwefelung (REA) zur Emissionskontrolle durch Reinigung des Gases, fand die Rotationsheizung eine weitere wertvolle Anwendung.

Viele Rauchgasentschwefelungsanlagen sind mit Gasüberhitzern (GGH) ausgestattet, um die Rauchgastemperatur vor dem Adsorber zu senken und das behandelte Gas wieder zu erwärmen, so dass ein „trockener“ Kamin entsteht. Dies gewährleistet einen ausreichenden Auftrieb der Abgasfahne und verhindert, dass die SO2-Konzentration am Boden über die festgelegten Grenzwerte hinaus ansteigt.

Der GGH reduziert den Wasserverbrauch im Adsorber und eliminiert die Ableitung von Flüssigkeit aus dem Kamin. Außerdem werden hohe Kosten für die Schornsteinsanierung und Wartungsprobleme aufgrund von Säurekorrosion und Abflussverstopfung vermieden.

Regenerative Gas-Gas-Wärmetauscher gewinnen Energie aus dem Rohgas zurück, wenn es in den REA-Wäscher eintritt, indem sie die Abwärme in dünnen metallischen Wärmeübertragungselementen absorbieren. Die Elemente drehen sich in der Regel mit etwa 0,5–1 U/min, um die Wärme an das behandelte Gas zu übertragen, das in den Schornstein geleitet wird.

Ziel: zur Unterstützung des SOX-Behandlungsprozesses und zur Kostensenkung durch Wiedererwärmung des behandelten Gases auf das erforderliche Auftriebsniveau.

Typische Prozesse, die bedient werden

Stickstoffoxid ist ein schädliches Gas, das bei der Verbrennung fossiler Brennstoffe entsteht. Als die selektive katalytische Reduktion (SCR) zur Emissionskontrolle eingeführt wurde, fand die Rotationsheizung eine weitere wertvolle Anwendung.

In einigen Werken, in denen die SCR-Anlage nicht am Economiser angebracht werden kann, wird die staubarme (oder hintere) SCR-Anlage zur Reduzierung der NOx-Emissionen eingesetzt.

Regenerative Gas-Gas-Wärmetauscher (GGH) gewinnen Energie aus dem behandelten Gas zurück, wenn es die SCR verlässt, indem sie die Abwärme in dünnen metallischen Wärmeübertragungselementen absorbieren. Bei dieser Anwendung rotieren die beheizten Elemente mit einer Drehzahl von 0,6–1 U/min, um die Wärme auf das Rohgas zu übertragen und so die zum Erreichen der Reaktionstemperatur erforderliche zusätzliche Erwärmung zu verringern.

Ziel: Zur Erhöhung der Effizienz des NOX-Emissionssystems durch Verringerung der zusätzlichen Heizung, die erforderlich ist, um die Reaktionstemperatur für die Zerstörung von NOX (≈ 250–330 oC) zu erreichen.

Typische Prozesse, die bedient werden

Da die Industrie auf Kohlenstoffabscheidung und -speicherung setzt, wird die Rotationsheiztechnologie in die Entwicklung von Lösungen integriert.

Für neue Kraftwerke werden Post Combustion Capture (PCC)-Lösungen für die Kohlenstoffabscheidung entwickelt. Für bestehende Kraftwerke lassen sich diese nachrüsten. Sie fangen Kohlendioxid (CO2) im Rauchgas ab, um es als Produkt zu nutzen oder dauerhaft unterirdisch einzulagern.

Das Heizgerät für dieses Verfahren ähnelt dem Gas-Gas-Wärmetauscher (GGH) mit ähnlichen Temperaturen wie beim REA-Verfahren. Das Heizgerät kombiniert die Kühlung des Rauchgases vor der FGD-Werk und die Wiedererwärmung des behandelten Gases nach der Kohlenstoffabscheidungsanlage für die Ableitung in den Schornstein.

Ziel: um die Temperatur des Rohgases vor der Abscheideanlage zu senken und das behandelte Gas damit wieder zu erwärmen, um die Sichtbarkeit der Abgasfahne zu verringern und genügend Auftrieb für den Austritt aus dem Schornstein zu haben.

Anwendbare Produkte

In vielen industriellen Prozessen wird bei hohen Temperaturen gebrannt. Diese Prozesse verbrauchen viel Energie, sodass jede Möglichkeit, den Bedarf zu senken, zu erheblichen Betriebseinsparungen führen kann.

Die Lösung von Howden stammt von unserer Marke Rothemühle und ihrem DREBS-Heizgerät. Hierbei handelt es sich um ein rotierendes Regenerator-Brennersystem, bei dem das Heizgerät die Energie der Hochtemperaturabgase auf keramische Heizflächen überträgt, die dann rotieren und die Wärme an den Luftstrom abgeben.

Im Vergleich zu herkömmlichen Rekuperatoren kann der DREBS für deutlich höhere Temperaturen von bis zu 1200 oC eingesetzt werden. Durch den hohen thermischen Wirkungsgrad von über 85 % kann die Energieeinsparung im Vergleich zu herkömmlichen Rekuperatoren verdoppelt werden.

Ziel: um den Wirkungsgrad von Brennern und Trocknern um bis zu 100 % gegenüber herkömmlichen Wärmetauschern zu erhöhen.

Typische Anwendungen

Howden befasst sich mit Regenerativheizungen seit der Gründung eines Joint Ventures im Jahr 1923 mit Fredrik Ljungström, dem Erfinder. Unsere eigene Produkttechnologie hat durch kontinuierliche Forschung, Entwicklung und Analyse zur Optimierung der Produktleistung und -zuverlässigkeit Designverbesserungen erfahren.

Im Jahr 2021 kam die Marke Rothemühle hinzu, die fast 90 Jahre Erfahrung mit Heizgeräten mitbrachte.

Unsere Fähigkeiten reichen von der Sicherstellung, dass unsere große globale Basis von Heizgeräten weiterhin für unsere Kunden funktioniert, bis zur Anpassung der Technologie an neue industrielle Anforderungen.

Unsere Heizgeräte arbeiten im Dauerbetrieb mit begrenzten Wartungsintervallen. Um die optimale Leistung aufrechtzuerhalten, verfügen wir über ein weltweites Team von Ingenieuren, die für die Wartung aller Rotationswärmetauscher unserer Eigenmarken Howden, Sirocco, Tallares Sanchez Luengo (TSL) und Rothemühle (einschließlich LUGAT) bereitstehen.

Da sich die Betriebsbedingungen von Werken im Laufe der Jahre ändern können, bieten wir eine Reihe von technischen Dienstleistungen zur Bewertung und Umsetzung von Leistungsverbesserungen und Lebensdauerverlängerungen an.

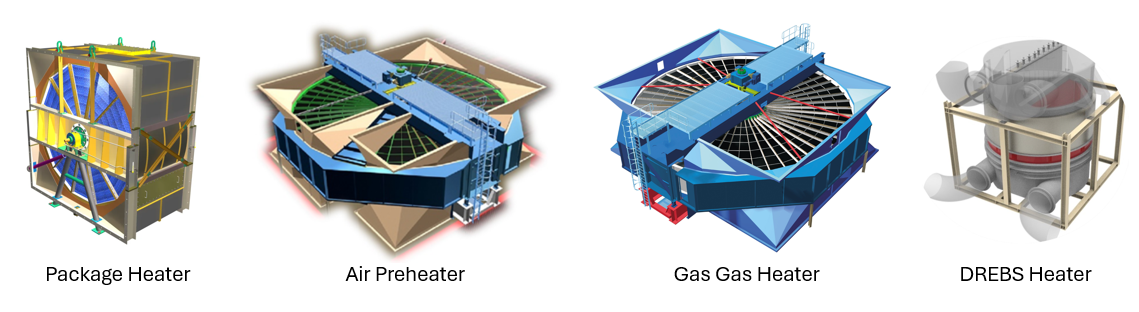

Howden-Heizgeräte arbeiten in einem breiten Spektrum von Gasmengen, Temperaturen und Aufstellflächen, um den Anforderungen verschiedener Prozesse und technischer Konfigurationen gerecht zu werden.

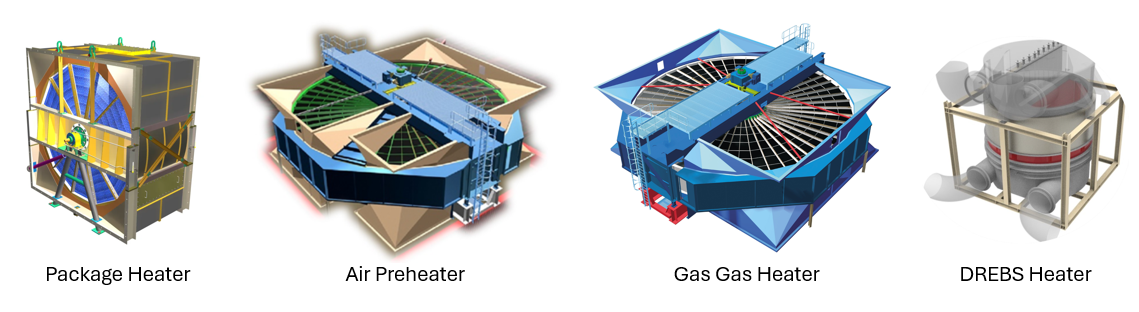

| Produkt | Thermische Energierückgewinnung | Gasvolumen | Gastemperatur | Fußabdruck | Leckage | Anwendungen |

|---|---|---|---|---|---|---|

| Heizgerätepakete | bis zu 15 MW | 45 bis 200 t/h | bis zu 370 oC (698 oF) | ca. 3,5 m2 bis 5,4 m2 | <5 % Verwendung von einfachen/doppelten radialen und doppelten axialen Dichtungen | Luftvorwärmung im kleineren Maßstab |

| Luftvorwärmer | bis zu 100 MW | 200 bis 3600 t/h | bis zu 500 oC (932 oF) | bis zu 625 m2 | <5 % Verwendung von Labyrinth-Mehrfachdichtungen mit optionalen Sektorplatten | Luftvorwärmung mit großem Volumen |

| Gasheizgerät | bis zu 100 MW | 200 bis 3600 t/h | bis zu 500 oC (932 oF) | bis zu 625 m2 | <0,5 % Verwendung von Labyrinth-Mehrfachdichtungen, Spül- und Spühlsystemen mit optionalen Sektorenplatten | Gasüberhitzung für FGD und Gasvorwärmung für SCR |

| DREBS-Heizgerät | bis zu 7 MW | bis zu 40 t/h | bis zu 1200 oC (2192 oF) | bis zu 16 m2 | Variabel je nach Druck und Anwendung | Hochtemperatur-Energierückgewinnung für Metall-, Glas- und Ofenanwendungen |

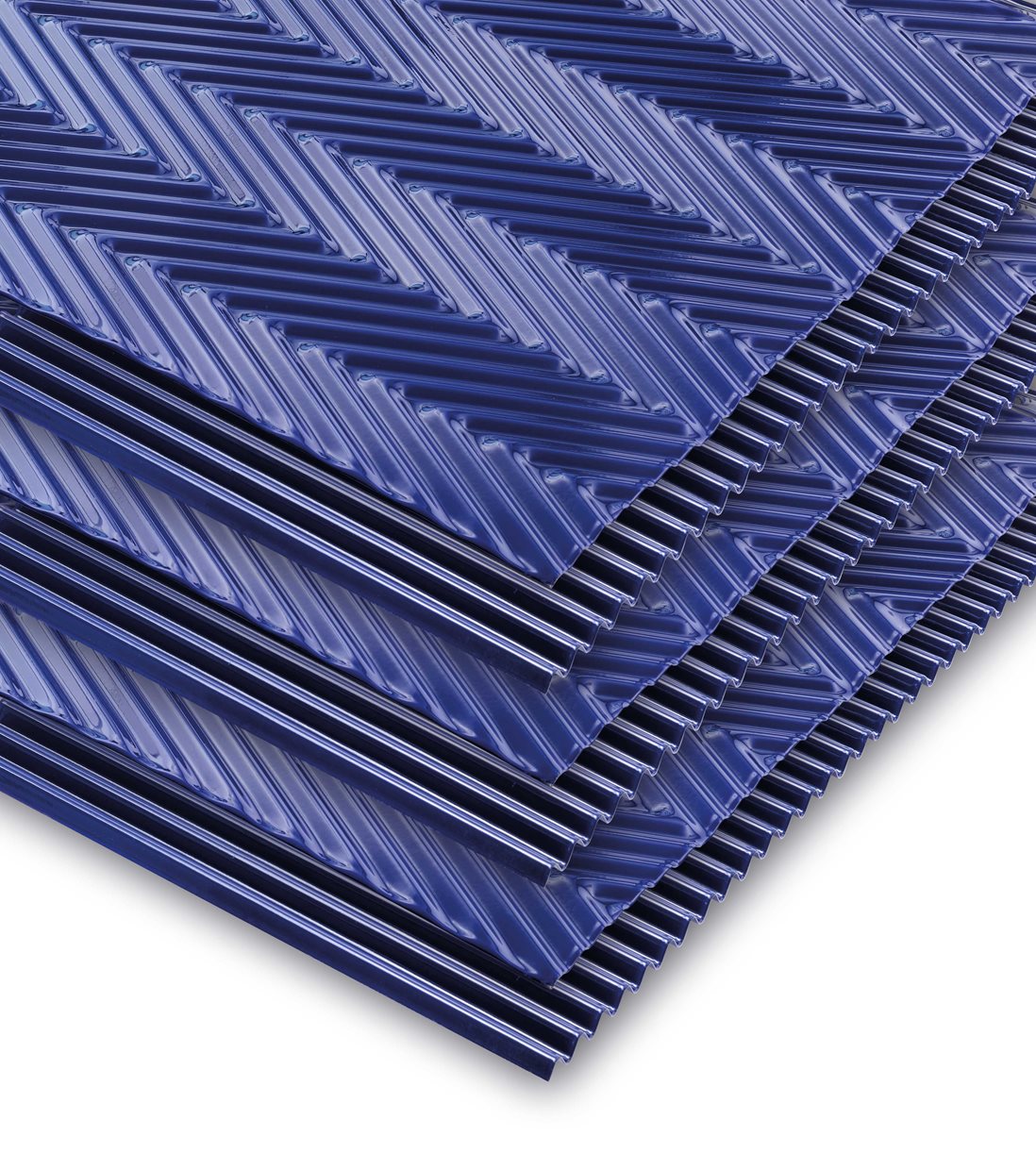

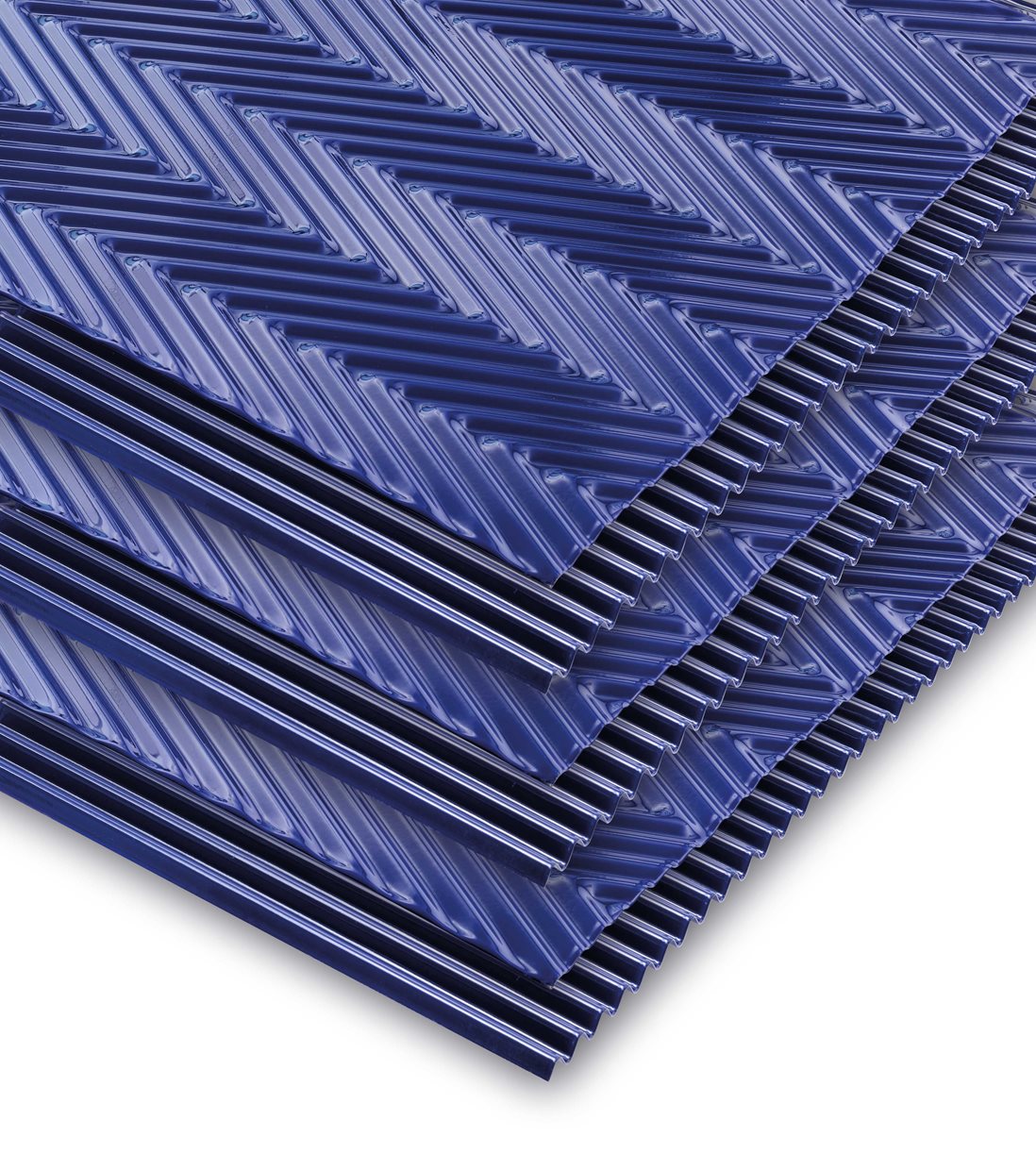

Um einen maximalen Wirkungsgrad zu erzielen, muss man genau wissen, wie das Heizgerät im Laufe der Zeit mit dem jeweiligen Brennstofftyp funktioniert. Die Wärmeübertragungselemente sind speziell für jede Anwendung und jeden Brennstoff ausgelegt.

Mit unserer breiten Profilpalette können wir die thermodynamische Leistung, den Druckabfall und die Einfachheit der Reinigung für jede Situation aufeinander abstimmen. Diese Profile können aus unserem Sortiment ausgewählt werden (zu dem das weltweit erste kommerziell erhältliche Doppel-Profil-Element gehört), oder wir können Profile liefern, die zu denen passen, über die Sie bereits verfügen.

Wir sind weltweit führend in der Herstellung emaillierter Elemente, die eine Kombination aus Korrosionsschutz und hoher Sauberkeit bieten, wenn diese in rauen Umgebungen eingesetzt werden.

Die Elemente spielen eine entscheidende Rolle für die Leistung des Heizgeräts, aber durch eine systematische Betrachtung der Wissenschaft des Verschmutzungs- und Reinigungszyklus haben wir ein integriertes System entwickelt, das weit mehr als die Summe seiner Teile bietet:

SureCoat™ (Hochleistungsemaillierung) + SurePack™ (optimierte Elementverpackung) + Enerjet™ (fortschrittliches Reinigungssystem).

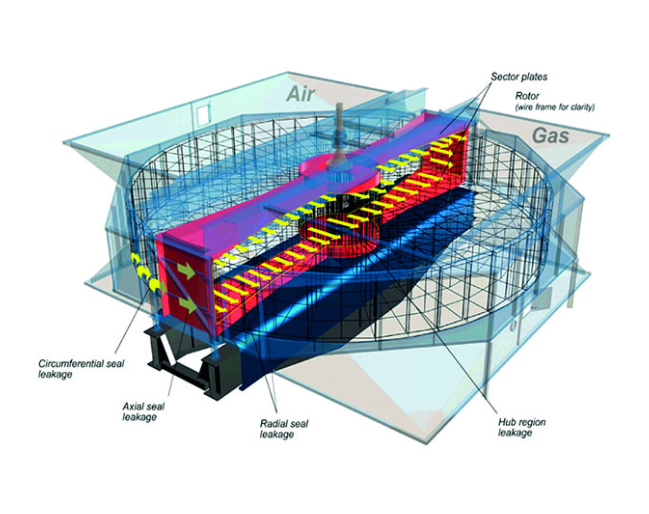

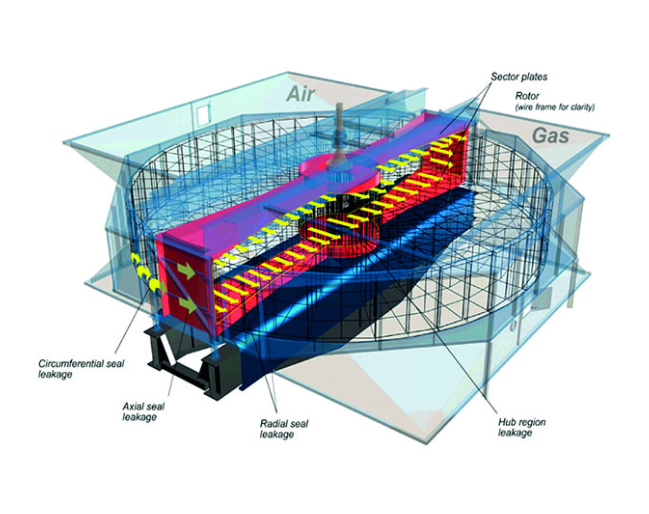

Die Minimierung von Gaslecks ist ein wichtiger Aspekt, und Howden hat eine Reihe von innovativen Lösungen entwickelt.

Das VN-Dichtungssystem hält die Leckage über einen längeren Zeitraum konstant niedrig. Bei GGHs werden zusätzliche Methoden angewandt, wie z. B. die Druckbeaufschlagung des Dichtungsraums mit Reingas unter Verwendung eines Spülgebläses, um einen leichten Druckunterschied zu erzeugen. Ein Absaugsystem leitet dann das verschmutzte Gas mit aufbereitetem Gas aus den Elementen ab.

KontaktdichtungenFlexible Kontaktdichtungen für Rotationswärmetauscher sind ein Verfahren zur Minimierung der direkten Leckagelücken zwischen dem heißen Ende des Rotors und den Sektorplatten, die den Luft- vom Gasstrom trennen.

Standarddichtungen brechen, da diese ständig gebogen werden. Daher hat Howden ein umfangreiches Entwicklungsprogramm durchgeführt, um Kontaktdichtungen für geeignete Anwendungen zu optimieren. So konnten Leckagen erheblich reduziert werden. Da die Dichtungen am besten dort funktionieren, wo die Abstände gering und die Spalte eben sind, können Leckagen durch die Kombination mit parabolischen Sektorplatten weiter reduziert werden.

Parabolische SektorplattenEine verstärkte Umweltkontrolle und die Nachfrage nach höchster Effizienz haben Howden dazu veranlasst, parabolische Sektorplatten für den Einsatz in unseren Heizgeräten zu entwickeln (diese sind zum Patent angemeldet).

Die Sektorplatten am heißen Ende mit ihrer variablen Steifigkeit sind so konzipiert, dass sie sich im Betrieb parabelförmig verformen, um sich an die Form des verformten Rotors im Betrieb anzupassen. Hierdurch wird der Spalt am heißen Ende möglichst klein gehalten, damit es nicht zu einer Leckage kommt.

Die parabolischen Sektorplatten von Howden senken nicht nur die Zuggebläseleistung in der Anlage, sondern auch den Gasmassenstrom zu nachgeschalteten Geräten zur Reduzierung der Emissionen.

Im Gegensatz zu Rohr- oder Plattenwärmetauschern führt die Verschmutzung bei regenerativen Rotationswärmetauschern nicht zu einer Verschlechterung der Wärmeübertragung. Verschmutzungen erhöhen die Druckunterschiede und damit die Ventilatorleistung und die Leckage. Wenn die Elemente jedoch sauber gehalten werden, wird eine hohe Verfügbarkeit aufrechterhalten und der Wartungsbedarf auf planmäßige Wartungsarbeiten beschränkt.

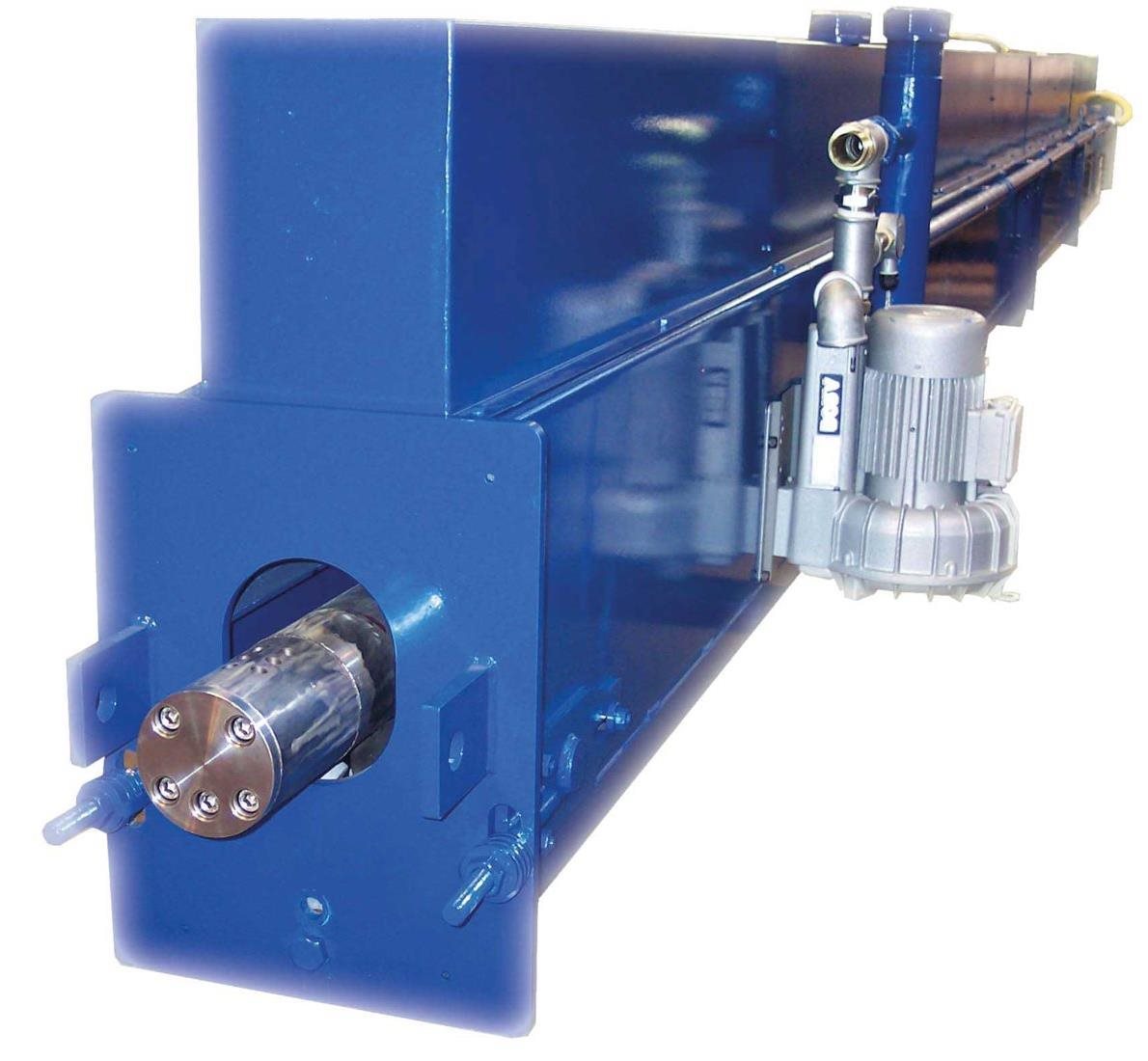

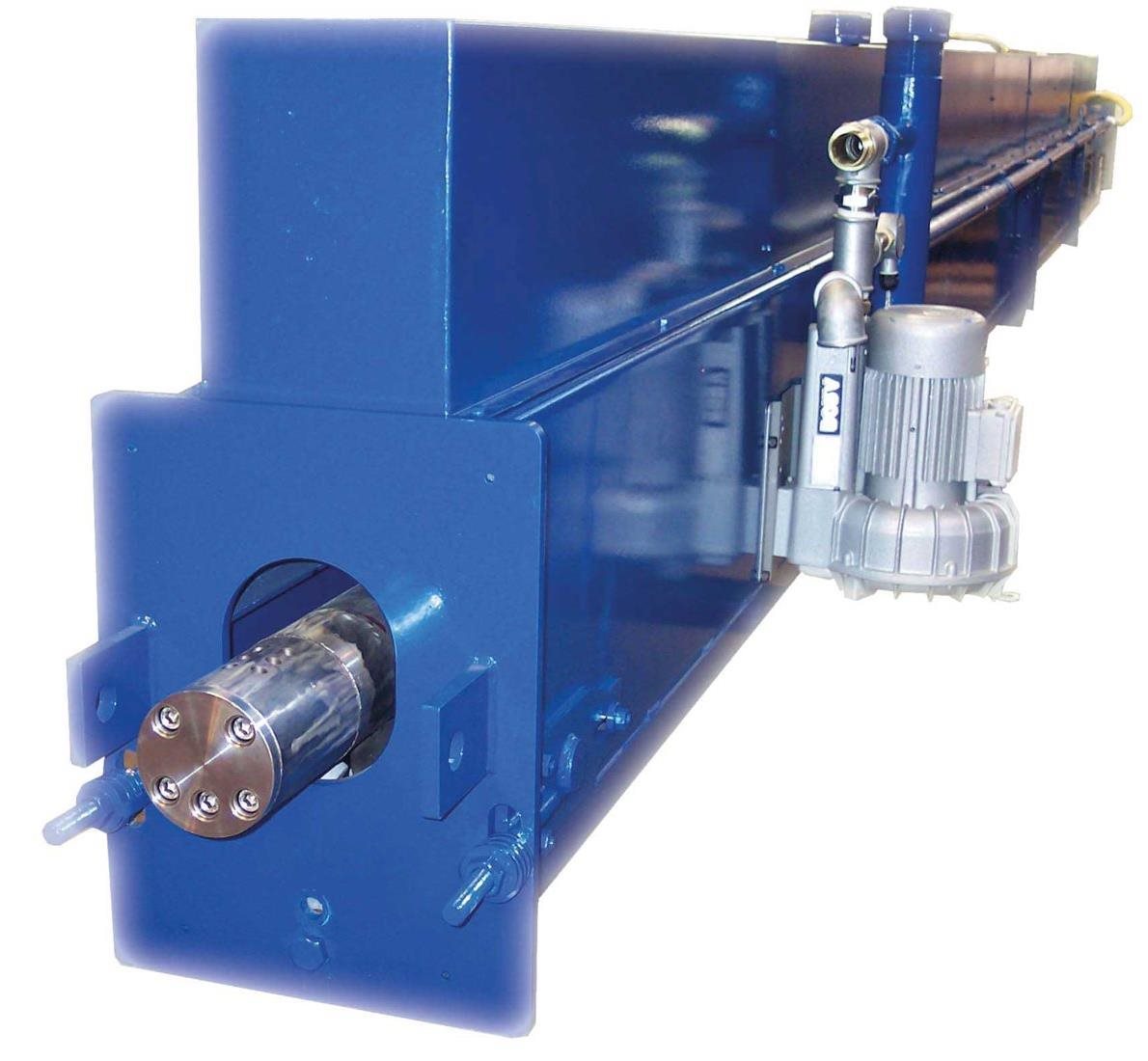

Das Reinigungssystem Howden Enerjet™ ist ein Verfahren zur Online-Hochdruckreinigung von Luftvorwärmern mit Wasser. Es wurde zur effektiven und effizienten Reinigung stark verschmutzter Wärmetauscherelemente im normalen Betrieb des Luftvorwärmers entwickelt.

Das System Enerjet™ kann zusammen mit einer Gasheizung jeder Art von jedem beliebigen Hersteller verwendet werden und funktioniert gut mit Elementprofilen der meisten Typen.

Enerjet™ in Kombination mit SureCoat™ (hochleistungsfähige emaillierte Elemente) und SurePack™ (optimierte Elementverpackung) bietet einen systematischen Ansatz für den Verschmutzungs- und Reinigungszyklus, der mehr als die Summe seiner Teile bietet.

Howden-Heizgeräte arbeiten in einem breiten Spektrum von Gasmengen, Temperaturen und Aufstellflächen, um den Anforderungen verschiedener Prozesse und technischer Konfigurationen gerecht zu werden.

| Produkt | Thermische Energierückgewinnung | Gasvolumen | Gastemperatur | Fußabdruck | Leckage | Anwendungen |

|---|---|---|---|---|---|---|

| Heizgerätepakete | bis zu 15 MW | 45 bis 200 t/h | bis zu 370 oC (698 oF) | ca. 3,5 m2 bis 5,4 m2 | <5 % Verwendung von einfachen/doppelten radialen und doppelten axialen Dichtungen | Luftvorwärmung im kleineren Maßstab |

| Luftvorwärmer | bis zu 100 MW | 200 bis 3600 t/h | bis zu 500 oC (932 oF) | bis zu 625 m2 | <5 % Verwendung von Labyrinth-Mehrfachdichtungen mit optionalen Sektorplatten | Luftvorwärmung mit großem Volumen |

| Gasheizgerät | bis zu 100 MW | 200 bis 3600 t/h | bis zu 500 oC (932 oF) | bis zu 625 m2 | <0,5 % Verwendung von Labyrinth-Mehrfachdichtungen, Spül- und Spühlsystemen mit optionalen Sektorenplatten | Gasüberhitzung für FGD und Gasvorwärmung für SCR |

| DREBS-Heizgerät | bis zu 7 MW | bis zu 40 t/h | bis zu 1200 oC (2192 oF) | bis zu 16 m2 | Variabel je nach Druck und Anwendung | Hochtemperatur-Energierückgewinnung für Metall-, Glas- und Ofenanwendungen |

Um einen maximalen Wirkungsgrad zu erzielen, muss man genau wissen, wie das Heizgerät im Laufe der Zeit mit dem jeweiligen Brennstofftyp funktioniert. Die Wärmeübertragungselemente sind speziell für jede Anwendung und jeden Brennstoff ausgelegt.

Mit unserer breiten Profilpalette können wir die thermodynamische Leistung, den Druckabfall und die Einfachheit der Reinigung für jede Situation aufeinander abstimmen. Diese Profile können aus unserem Sortiment ausgewählt werden (zu dem das weltweit erste kommerziell erhältliche Doppel-Profil-Element gehört), oder wir können Profile liefern, die zu denen passen, über die Sie bereits verfügen.

Wir sind weltweit führend in der Herstellung emaillierter Elemente, die eine Kombination aus Korrosionsschutz und hoher Sauberkeit bieten, wenn diese in rauen Umgebungen eingesetzt werden.

Die Elemente spielen eine entscheidende Rolle für die Leistung des Heizgeräts, aber durch eine systematische Betrachtung der Wissenschaft des Verschmutzungs- und Reinigungszyklus haben wir ein integriertes System entwickelt, das weit mehr als die Summe seiner Teile bietet:

SureCoat™ (Hochleistungsemaillierung) + SurePack™ (optimierte Elementverpackung) + Enerjet™ (fortschrittliches Reinigungssystem).

Die Minimierung von Gaslecks ist ein wichtiger Aspekt, und Howden hat eine Reihe von innovativen Lösungen entwickelt.

Das VN-Dichtungssystem hält die Leckage über einen längeren Zeitraum konstant niedrig. Bei GGHs werden zusätzliche Methoden angewandt, wie z. B. die Druckbeaufschlagung des Dichtungsraums mit Reingas unter Verwendung eines Spülgebläses, um einen leichten Druckunterschied zu erzeugen. Ein Absaugsystem leitet dann das verschmutzte Gas mit aufbereitetem Gas aus den Elementen ab.

KontaktdichtungenFlexible Kontaktdichtungen für Rotationswärmetauscher sind ein Verfahren zur Minimierung der direkten Leckagelücken zwischen dem heißen Ende des Rotors und den Sektorplatten, die den Luft- vom Gasstrom trennen.

Standarddichtungen brechen, da diese ständig gebogen werden. Daher hat Howden ein umfangreiches Entwicklungsprogramm durchgeführt, um Kontaktdichtungen für geeignete Anwendungen zu optimieren. So konnten Leckagen erheblich reduziert werden. Da die Dichtungen am besten dort funktionieren, wo die Abstände gering und die Spalte eben sind, können Leckagen durch die Kombination mit parabolischen Sektorplatten weiter reduziert werden.

Parabolische SektorplattenEine verstärkte Umweltkontrolle und die Nachfrage nach höchster Effizienz haben Howden dazu veranlasst, parabolische Sektorplatten für den Einsatz in unseren Heizgeräten zu entwickeln (diese sind zum Patent angemeldet).

Die Sektorplatten am heißen Ende mit ihrer variablen Steifigkeit sind so konzipiert, dass sie sich im Betrieb parabelförmig verformen, um sich an die Form des verformten Rotors im Betrieb anzupassen. Hierdurch wird der Spalt am heißen Ende möglichst klein gehalten, damit es nicht zu einer Leckage kommt.

Die parabolischen Sektorplatten von Howden senken nicht nur die Zuggebläseleistung in der Anlage, sondern auch den Gasmassenstrom zu nachgeschalteten Geräten zur Reduzierung der Emissionen.

Im Gegensatz zu Rohr- oder Plattenwärmetauschern führt die Verschmutzung bei regenerativen Rotationswärmetauschern nicht zu einer Verschlechterung der Wärmeübertragung. Verschmutzungen erhöhen die Druckunterschiede und damit die Ventilatorleistung und die Leckage. Wenn die Elemente jedoch sauber gehalten werden, wird eine hohe Verfügbarkeit aufrechterhalten und der Wartungsbedarf auf planmäßige Wartungsarbeiten beschränkt.

Das Reinigungssystem Howden Enerjet™ ist ein Verfahren zur Online-Hochdruckreinigung von Luftvorwärmern mit Wasser. Es wurde zur effektiven und effizienten Reinigung stark verschmutzter Wärmetauscherelemente im normalen Betrieb des Luftvorwärmers entwickelt.

Das System Enerjet™ kann zusammen mit einer Gasheizung jeder Art von jedem beliebigen Hersteller verwendet werden und funktioniert gut mit Elementprofilen der meisten Typen.

Enerjet™ in Kombination mit SureCoat™ (hochleistungsfähige emaillierte Elemente) und SurePack™ (optimierte Elementverpackung) bietet einen systematischen Ansatz für den Verschmutzungs- und Reinigungszyklus, der mehr als die Summe seiner Teile bietet.

Hauptsitz +44 141 885 7500

Heizgerätepakete +34 968 32 00 64